Hi from Jenn!

Let me tell you about my glass journey.

It all started when I was given a dichroic necklace as a gift, I was captivated by its sparkle. I needed to learn how to make things that beautiful!

My new hobby began with a “DIY” kiln, and some glass exploration. I started learning how glass works using different techniques, shapes, glass and colours to discover what I needed to create jewellery. After two kiln upgrades and all of this learning, here is my website!

I hope you enjoy looking through my creations and fall in love with glass too.

If you have come here because Annette sent you then, hello! She is my biggest fan 🙂

I am often squirrelled away making glass, so please check back regularly for new items and feel free to contact me if you have any questions, or would like to talk with me about a commission piece.

What is Curious Glass jewellery made from?

It’s made from glass. Glass fusing is the technique of joining two or more pieces of clear and/or coloured glass by heat.

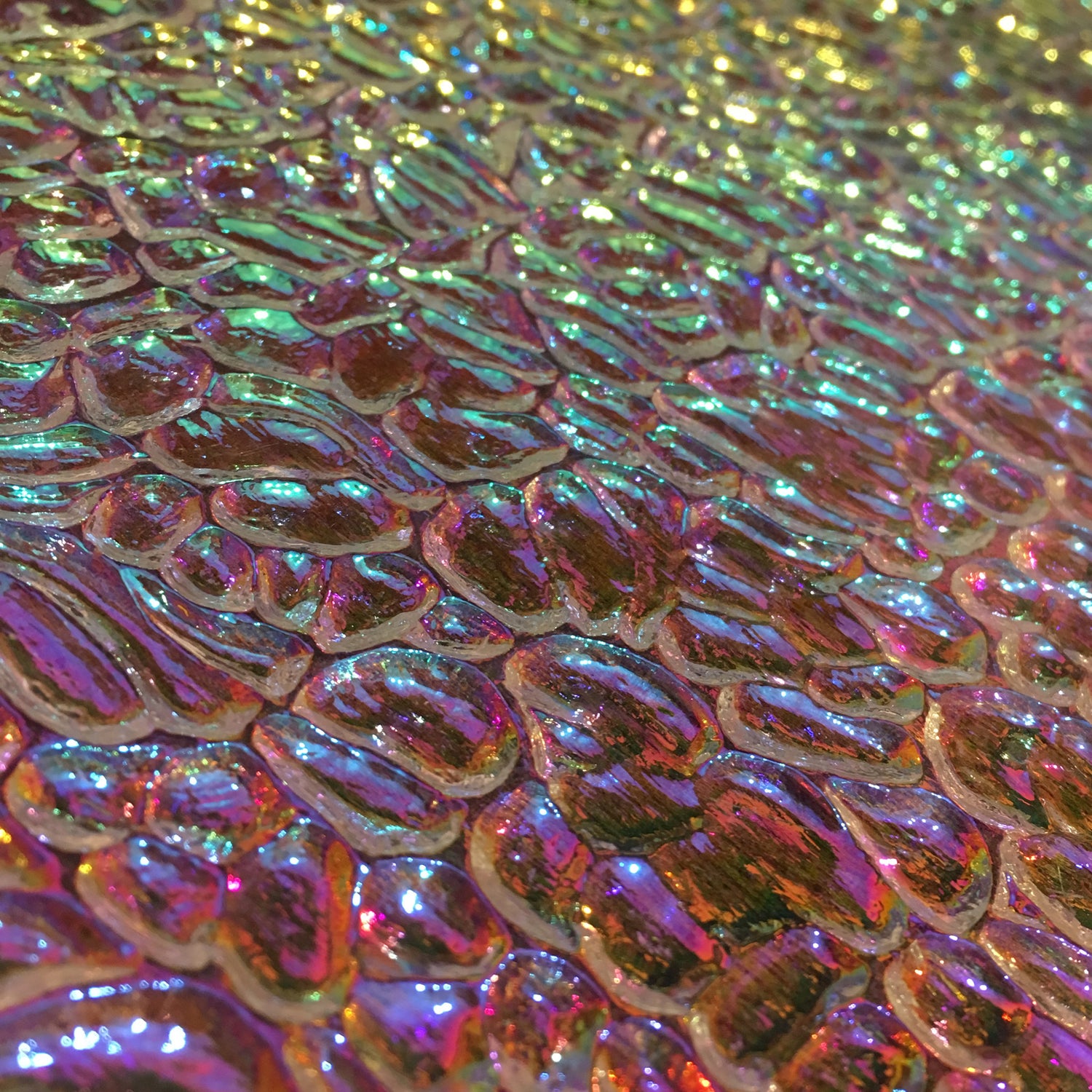

I like to work with opaque and translucent coloured but my favourite is dichroic glass. It is beautifully sparkly and has such depth of colour which is hard to capture in photographs, it’s so eye catching and unique.

What type of glass does Curious Glass work with?

Dichroic (di-crow-ick) means “Two Colours”. This means that the colours of the same piece will look different depending on the angle of the photograph.

Originally created for the Aerospace industry, Dichroic Glass is now made available to the artist community through Coatings by Sandberg, Inc. CBS Dichroic Glass is specifically designed to be hot worked in any way but can also be used in its raw form. The main characteristic of Dichroic Glass is that it has a transmitted colour and a completely different reflective colour. Furthermore, these two colours shift depending on angle of view.”

How does Curious Glass make a necklace?

A necklace starts with sheets of specialised coloured glass. I use a glass cutter to score the glass into various shapes. Sometimes the glass cuts as I want and other times it does what it wants!

I layer glass on top of each other. For example, the “Classic” collection will have 3 layers of glass. However, for the “Signature” collection there are 10+ pieces of glass.

Next, I put the glass in my kiln and it will carefully make it's way up to a temperature of 800°C. This process can take 12+ hours.

It doesn’t matter how many times I’ve opened the kiln, it’s still exciting! With the nature of glass, I can’t predict exactly how the glass will fall. I know a genuinely unique piece of jewellery will come out and no two pieces will ever be the same.

After they have been through the kiln they mostly need to be machine ground to make sure the edges a perfect! They then go back in the kiln to make them all shiny.

If I'm making earrings, I have to grind the two pieces of glass individually to try and get them to match in shape as best as I can. They often end up as sisters not twins! That is the nature of handmade jewellery.

Lastly, the jewellery is ready to have a bail glued on to the back of it so that it can hang off a necklace chain. Once that is done, I string the necklaces onto a 925 silver chain and place it in a box that is recyclable after use.

Thank you for your interest in how I make my jewellery and I hope you find something special for yourself or a loved one.